New solution for achieving complex shapes while reducing raw material waste

Slurry conditioned material is casted into product-shaped mold and formed by solidification.

This is Kyocera's new forming method which enables near-net shapes, and is expected to expand ceramics' applications further.

Parts developed via F-Molding have the same or better characteristics compared to those produced by CIP (Cold Isostatic Pressing) forming.

Features

- Unique and Complex Shaped Part FormingAchieves complex designs which can not be achieved by conventional green machining and grinding.

- Near-Net Shape FormingCost savings achieved by reducing material waste with less machining (compared to CIP forming)

- Small Volume Orders AvailableInitial cost saving with less expensive mold (compared to injection molding and press forming)

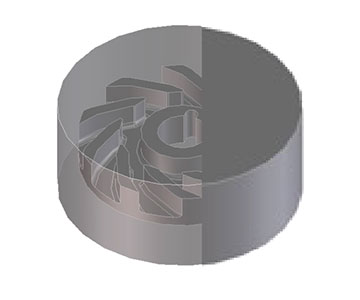

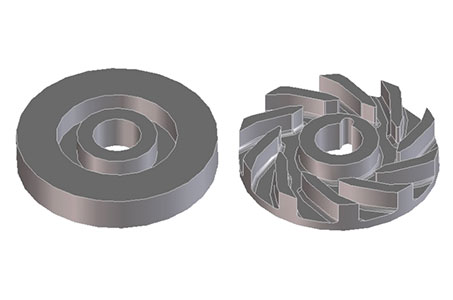

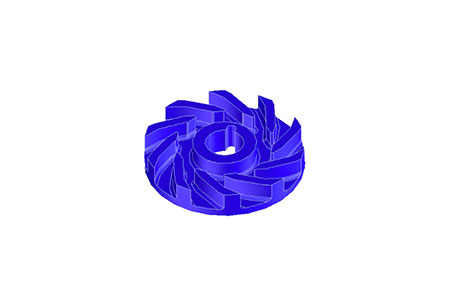

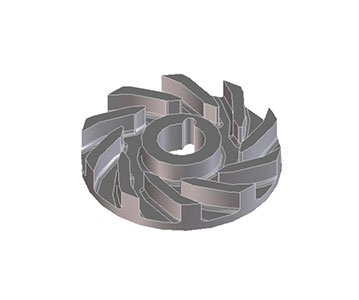

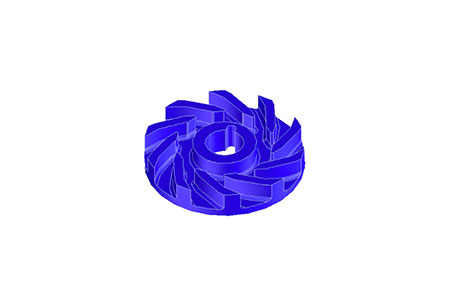

Design Samples

Material: Zirconia (ZO 206 N) Size: Φ 50 mm

Material: Silicon Nitride (SN 240 O) Size: Φ 50 mm

*Please ask us about available sizes.

Manufacturing Process

Conventional Method

CIP forming +

Green machining

Forming a cylindrical ceramic block

Green Machining into shape

After sintering, final grinding

New Method

F-Molding

Molding into near-net shape

- No green machining process

- ・Reduction of raw material waste

・Reduction of processing time

After firing, final grinding

Material Lineup

| Material Material Code |

Zirconia | Cordierite | Silicon Nitride | ||||

|---|---|---|---|---|---|---|---|

| ZO206N | CO220O | CO720O | SN240O | ||||

| Color | - | White | Gray | Gray | Black | ||

| Density | g/cm3 | 6.0 | 2.50 | 2.54 | 3.3 | ||

| Mechanical Characteristics | Vickers Hardness HV9.807N | GPa | 12.0 | 8.0 | 8.5 | 14.0 | |

| Flexural Strength (3-point Bending) | MPa | 1,100 | 190 | 200 | 1,020 | ||

| Young’s Modulus | GPa | 210 | 140 | 145 | 300 | ||

| Poisson’s Ratio | - | 0.32 | 0.31 | 0.31 | 0.28 | ||

| Fracture Toughness (SEPB) | MPa・m1/2 | 6 | 1-1.5 | 1-1.5 | 7 | ||

| Thermal Characteristics | Coefficient of Linear Thermal Expansion | 40-400℃ | × 10-6/K | 10.4 | (*) 1.5 | (*) 1.5 | 2.8 |

| 40-800℃ | 10.8 | (*) 2.1 | (*) 2.1 | 3.3 | |||

| Thermal Conductivity | 20℃ | W/ (m・K) | 3 | 4 | 4 | 27 | |

| Specific Heat Capacity | J/ (g・K) | 0.44 | 0.71 | 0.74 | 0.65 | ||

| Thermal Shock Resistance (quenching into water) |

℃ | 300 | 450 | 400 | 800 | ||

* <|0.05|(23℃)、<|0.02|(22℃)

Materials not listed in the table are under development, please feel free to contact us for further information.

All values listed on this page are representative values obtained from in-house measurements,

and do not constitute guaranteed product specifications.